Prevent Mining Disasters with Carbon Fiber

Boosting Mining Safety: Reinforcing Structures for a Safer Future

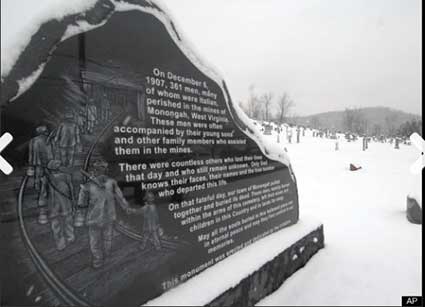

Mining remains one of the most hazardous occupations globally. Every year, countless mining accidents result in tragic fatalities, frequently caused by collapses, explosions, or fires. Although there has been a significant decrease in mining accidents and related deaths over the past few decades, mining operations still pose considerable risks. The Mine Safety and Health Administration (MSHA) records that 1907 marked the "deadliest year in U.S. coal mining history," with approximately 3,242 fatalities, including the Monongah mine explosion in West Virginia, which claimed 361 lives. Despite substantial advancements in mining safety regulations since the 1970s, recent incidents, like the devastating mining explosion in Turkey, highlight the ongoing dangers miners face.

A "mining disaster" is defined as an event causing the death of five or more individuals. In the United States, since 1976, fewer than 20 mining disasters have occurred, compared to the 526 disasters between 1901 and 1950. While data from MSHA and other agencies show a notable decline in mining accidents and fatalities in the U.S., the situation remains troubling in other regions. China, for example, still experiences a high number of mining fatalities, with over a thousand reported last year, despite recent safety improvements. China also holds the grim record for the world’s deadliest mining disaster, which occurred in April 1942 when 1,549 miners lost their lives. Recent mining accidents are also widespread, including the 2010 Chilean mining disaster, where 33 miners were trapped underground for two weeks, and thankfully, 31 survived. Just two weeks ago, five miners died in a mine collapse in Bosnia, and in August, another 25 lives were claimed in a rebel-held mine in the Central African Republic town of Bombari. Several other mining accidents have occurred in the past decade, including multiple incidents this year.

The pressing question is whether anything can be done to enhance global mining safety. The answer is undoubtedly yes. At HJ3, we have made a significant impact on improving the structural integrity of many mines in the Southwestern United States by reinforcing their concrete and steel structures. A large number of modern mine collapses are linked to vibrations caused by heavy equipment use, and reinforcing the support systems can greatly reduce the risk of structural failure due to these vibrations. Given that many mines are over a century old, their concrete beams and columns have corroded due to prolonged exposure to vibrations, moisture, sulfuric acid, and the mines’ electro-winning processes.

Some of the mines that HJ3 has reinforced were so deteriorated that they faced the threat of being shut down by MSHA. Using CarbonSealâ„¢'s glass composite and carbon fiber fabrics, these mines have seen a remarkable revival, with columns and beams now offering more robust support than they have in over a century. Our composite systems are ten times stronger than steel, highly resistant to chemicals, and perfect for reinforcing structures under harsh mining conditions. Moreover, the lightweight, flexible fabric form of these systems is particularly advantageous for narrow or hard-to-reach spaces.

If you know of a mine in need of structural reinforcement, we invite you to join HJ3 in our mission to protect lives and resources. For more information, please contact us at .

â€

Seamless Aluminium Tubing,Seamless Rectangualr Pipe,Seamless Pipe Connection

Guangdong Tonglian Pipeline Technology Co., Ltd , https://www.tonglianpipeline.com