Differences between Single-layer, Double-layer and Multi-layer FPC

Flexible Printed Circuits (FPCs) have become a key component in modern electronics due to their flexibility, lightweight design, and high-density capabilities. Depending on the number of layers, FPCs can be categorized into single-layer, double-layer, and multi-layer types, each with distinct structural features, performance characteristics, and application areas. This article will explore the differences between these three types of FPCs and help you understand which one might be best suited for your needs.

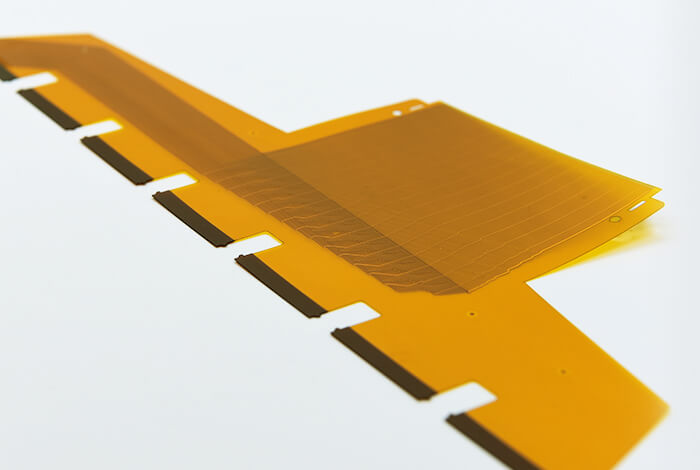

Single-Layer FPC

The simplest form of flexible printed circuit is the single-layer FPC, which consists of just one conductive copper layer and a substrate. The copper layer is etched with a specific circuit pattern, and a protective coverlay is applied on top to ensure durability and insulation.

Structure:

- Substrate (such as polyimide or PET)

- Copper foil

- Coverlay (for protection)

Characteristics:

- Simple and cost-effective: With only one conductive layer, it's easier to manufacture and more affordable.

- High flexibility: Ideal for applications requiring bending or folding without compromising functionality.

- Reliable for basic use: Due to its minimal structure, it’s less prone to failure and suitable for simple connections.

Applications:

Commonly used in devices that require simple wiring and flexibility, such as printers, scanners, and basic display interfaces.

Double-Layer FPC

A double-layer FPC includes two copper layers separated by an insulating substrate. These layers are connected through vias, allowing for more complex circuit designs compared to single-layer boards.

Structure:

- Coverlay

- Top copper foil

- Substrate

- Bottom copper foil

- Coverlay

Characteristics:

- More complex circuitry: Allows for circuits on both sides, increasing design versatility.

- Higher circuit density: Supports more components and connections in a compact space.

- Better reliability: Offers improved performance in applications where stability is essential.

Applications:

Used in devices like smartphones, digital cameras, and medical equipment where more advanced circuitry is required.

Multi-Layer FPC

Multi-layer FPCs consist of multiple copper layers stacked together with insulating substrates and adhesive layers in between. Vias connect the layers, enabling highly complex and dense circuit designs.

Structure:

- Coverlay

- Top copper foil

- Substrate

- (Adhesive + Copper foil + Substrate) × N (repeated layers)

- Bottom copper foil

- Coverlay

Characteristics:

- Supports high-density and complex designs: Perfect for applications requiring intricate layouts.

- Improved signal integrity: Helps reduce electromagnetic interference and enhance performance.

- Greater design flexibility: Enables efficient use of space and optimized layout options.

Applications:

Primarily found in high-end devices such as advanced smartphones, tablets, aerospace systems, and precision medical instruments.

Each type of FPC offers unique benefits depending on the application. Single-layer FPCs are ideal for simple and flexible connections, while double-layer FPCs offer better performance and density. Multi-layer FPCs, on the other hand, are designed for the most demanding and complex electronic systems. Understanding the differences between them can help you make an informed decision when selecting the right FPC for your project, ensuring optimal performance and long-term reliability.

H Beam Steel,H Beams Steel,Steel H Beam,Hot Steel H Beam Steel

Shandong Rizhaoxin Metal Products Co., Ltd. , https://www.changyisteel.com