“Get Your Fix†Part 2 of 10: YORK® YLAA

“Get Your Fix†Part 2 of 10: YORK® YLAA

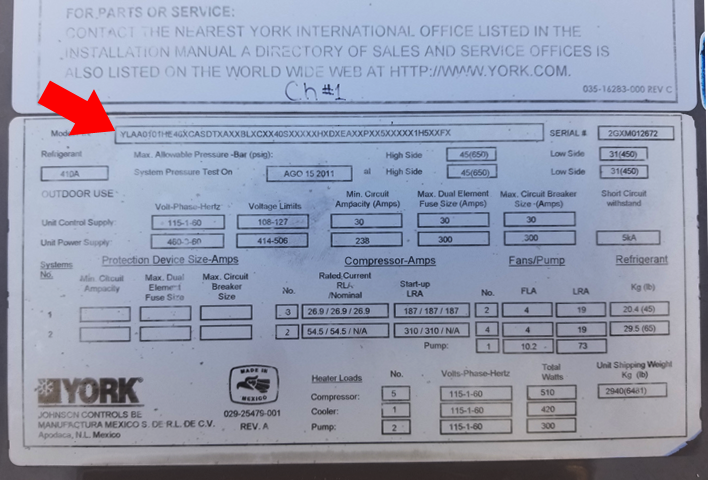

Continuing our countdown of the top ten commercial OEM condenser coils that have faced issues over the past decade, we now look at the YORK® YLAA series — a unit that has seen its fair share of service challenges and durability concerns.

As we continue our coil issue countdown, we're focusing on the YORK® YLAA chiller — a model known for its operational problems and poor performance from its original microchannel condenser coils. We regularly receive calls from contractors and end users about leaks and reliability issues with this unit.

Overall, customers are dissatisfied with the durability of this OEM model, which has affected York’s reputation. While the unit was available with both microchannel and copper tube coils, the latter is rarely seen in the field. That’s why many opt for a conversion to copper tubes for better long-term performance.

The usual suspects

The most common YLAA units we encounter are the Style B models, which come standard with microchannel condenser coils in both regular and high-efficiency versions. Identifying whether it's a standard or high-efficiency unit is easy by checking the model number. For example, "S" in YLAA0700SE stands for standard, while "H" in YLAA0156HE means high efficiency. If you see "ZE" in the model number, like YLAA0080ZE, it originally had copper tube coils.

So, what’s the solution?

Converting the microchannel in the YORK® YLAA chiller to a copper tube condenser coil can significantly improve reliability and ease of maintenance without sacrificing OEM efficiency.

One important thing to remember: when upgrading from microchannel to copper tubes, you must replace the entire circuit. If one coil is leaking in a system with four coils, all four need to be replaced. Depending on the unit size, YLAA chillers can have between 4 to 12 coils.

A York YLAA unit before microchannel conversion.

The same York YLAA unit after converting to copper tubes with a Blygold® coating.

If you only want to replace one coil, we recommend contacting York directly for an MCHX coil. At Nationwide Coils, we don’t offer partial replacements because they’re just temporary fixes and won’t resolve the ongoing issues with the YLAA unit.

While the YORK YLAA is one of the more popular units we upgrade, we can perform a microchannel conversion on any make or model. It's a smart move for long-term performance and fewer headaches down the line.

The Nationwide Coils Blog is a commercial HVAC blog written by industry experts with almost two decades of experience. We provide valuable insights into commercial HVAC products and services and encourage you to email us anytime.

The connecting rod is an important part of the car engine and plays a vital role in the overall function of the engine. Its main purpose is to connect the piston to the crankshaft and convert the reciprocating motion of the piston into the rotational motion of the crankshaft. The application of automotive engine connecting rods is crucial to the normal operation of the engine. It ensures power transfer, provides strength and durability, helps reduce weight, aids in engine balance and allows customization for various engine requirements

Fiat Connecting Rod,Car Engine Connecting Rods,Aluminum Connecting Rods,Car Connecting Rods

Wuhu Hangtian Automobile Connecting Rod Co., Ltd , https://www.htconrod.com