“Get Your Fix†Part 2 of 10: YORK® YLAA

“Get Your Fix†Part 2 of 10: YORK® YLAA

Continuing our countdown of the top ten commercial OEM condenser coils that have faced service issues over the past decade, we now spotlight the YORK® YLAA series. This unit has been a frequent topic of concern among contractors and end users due to its problematic microchannel condenser coils.

As we continue our coil issue countdown, we're focusing on the YORK® YLAA chiller—a unit that has consistently faced operational challenges and durability concerns, especially with its MCHX condenser coils. In fact, we receive multiple calls each week from contractors and building operators about leaks and failures in the original microchannel coils.

Many customers are frustrated with the performance of this OEM model, which has negatively impacted York’s reputation. While the YLAA was available with both microchannel and copper tube coils, the latter is rarely seen in the field—most units come equipped with the less durable microchannel version.

The usual suspects

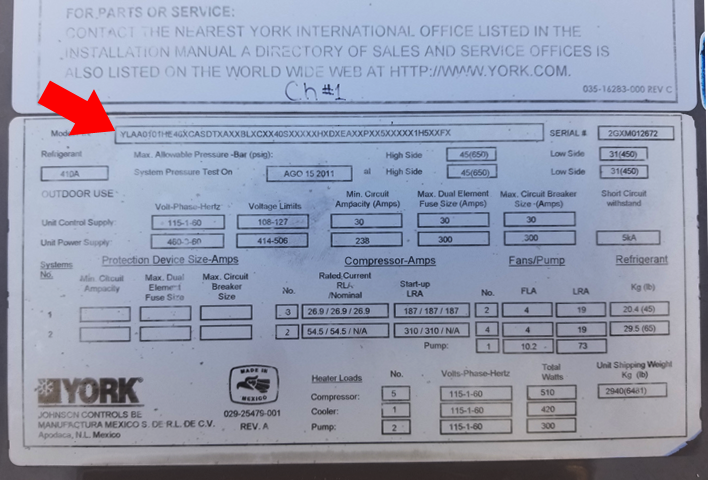

The most commonly encountered YLAA units are the Style B models, which feature microchannel condenser coils in both standard and high-efficiency versions. Identifying whether you're dealing with a standard or high-efficiency unit is simple: check the model number. For example, "S" in YLAA0700SE stands for standard, while "H" in YLAA0156HE indicates high efficiency. If you see "ZE" in the model number, like in YLAA0080ZE, that unit originally came with copper tube coils.

So, what's the solution? #ChangeTheChannel

Converting the microchannel coil in the YORK® YLAA chiller to a copper tube condenser coil can significantly improve reliability and make servicing easier, all while maintaining OEM efficiency levels.

One important thing to note: when upgrading from microchannel to copper tubes, it’s essential to replace the entire circuit. If one coil is leaking and it’s part of a system with four coils, all four must be replaced. Depending on the unit size, YLAA chillers can have between 4 to 12 coils.

A York YLAA unit before microchannel conversion.

The same York YLAA unit after converting to copper tubes and applying a Blygold® coating.

If you only want to replace one coil, we recommend contacting York directly and purchasing an MCHX coil from them. At Nationwide Coils, we don’t just replace one coil because it’s a temporary fix and won’t resolve the underlying issues with the YLAA unit.

Although the YORK YLAA is one of the more popular units we convert, we offer microchannel conversions for any make or model. Whether you're looking to upgrade your existing system or prevent future issues, we’re here to help.

The Nationwide Coils Blog is a commercial HVAC blog written by industry experts with nearly two decades of experience in the field. We provide valuable insights into commercial HVAC products and services and encourage you to email us anytime with your questions or feedback.

Connecting rods are a key component of Nissan's engine. It connects the piston to the crankshaft and helps to convert the reciprocating motion of the piston into the rotational motion of the crankshaft.

Connecting rods are usually made of high-strength steel or aluminum alloys to withstand the high forces and temperatures generated in the engine. It is designed to be lightweight and durable to keep the engine running efficiently.

Nissan uses advanced manufacturing techniques and materials to ensure the quality and performance of the connecting rods. They go through rigorous testing and quality control measures to ensure they meet the highest standards.

Nissan Connecting Rod,Venolia Connecting Rod,Tuscan Connecting Rods,Adept Connecting Rod

Wuhu Hangtian Automobile Connecting Rod Co., Ltd , https://www.htconrod.com