Converting the Microchannel Coil in the Lennox® LCH156H4: Improve performance and reliability

Upgrading the Microchannel Coil in the Lennox® LCH156H4: Boost Performance and Longevity

Tired of frequent leaks and maintenance headaches with your Lennox LCH156H4 rooftop unit? Discover a cost-effective microchannel coil conversion that enhances efficiency, reliability, and system life.

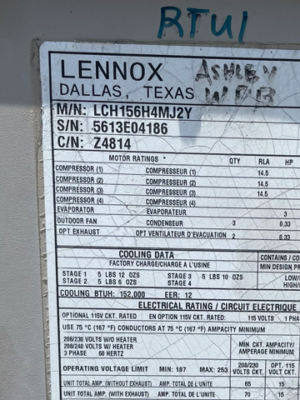

When it comes to replacing commercial condenser coils, the Lennox LCH156H4 is often at the top of the list. This popular rooftop unit is known for its performance, but it also comes with some common issues—especially when it's equipped with all-aluminum microchannel coils.

One of the most effective solutions is converting the microchannel coil to a copper tube, aluminum fin coil. While microchannel coils have been widely used for their low cost and reduced refrigerant charge, they come with several drawbacks that can impact long-term performance and maintenance.

The Challenges of Microchannel Coils

Microchannel coils are prone to dirt buildup, which can lead to higher head pressure and inefficient operation if not cleaned regularly. They also require precise refrigerant charging due to their low refrigerant capacity. Repairing these coils is difficult and often requires specialized techniques like two-part epoxy or torch welding, which can be time-consuming and risky. Plus, aluminum is more susceptible to corrosion and weather damage, increasing the likelihood of leaks at the connection points between copper and aluminum components.

Why Upgrade to a Copper Tube, Aluminum Fin Coil?

Switching to a high-quality copper tube, aluminum fin coil offers numerous benefits. These coils are more durable, easier to maintain, and significantly less prone to leaks. One of the biggest advantages is the ability to pump down the system during repairs. Unlike microchannel coils, which use flat plates with tiny holes that limit refrigerant capacity by up to 30%, copper tube coils allow compressors to pump refrigerant directly into the condenser, eliminating the need to recover the entire system before making repairs. This saves both time and money.

Additionally, copper tube coils offer better long-term cost efficiency by reducing the frequency of repairs and minimizing refrigerant loss from leaks. Over time, this makes them a smarter investment for any commercial HVAC system.

Understanding the Circuit Requirements

When replacing microchannel coils with copper tube coils, it’s essential to complete the circuit properly. For example, if your unit has four coils per circuit and one is damaged, you must replace all four. This is because copper tube coils have different refrigerant pressure drops compared to microchannel coils. Mixing the two types within the same circuit can cause operational inefficiencies and even system failure. Ensuring consistency across the entire system is key to maintaining optimal performance.

Expertise in Microchannel Conversion

While the Lennox LCH156H4 is a common unit that benefits from a microchannel conversion, this upgrade is available for all major commercial HVAC brands. With years of experience and thousands of conversions completed, Nationwide Coils has become a trusted name in the industry. Our team of experts specializes in providing reliable, high-performance solutions tailored to your specific needs.

If you're looking to improve the efficiency, reliability, and lifespan of your HVAC system, consider a microchannel conversion. Contact us today at 1.888.CoilPro or email us for a free consultation. All we need is your unit’s make and model number to get started on your upgrade.

Variable valve timing (VVT) solenoid or oil control valve controls the oil flow according to the engine speed and load. VVT solenoid is a vital part of the variable valve timing system.

The Oil Control Valve (OCV) is a a critical part used in every engine that is fitted with variable valve technology (VVT). A single control valve will regulate the supply of oil to a designated VVT hub, to advance or retard the timing by altering the camshaft angle position. Controlled by the ECU, the OCV receives electrical signals, instructing it to adjust the oil flow as required, in accordance to current driving conditions.

Nissan Variable Valve Timing,Nissan Vvt Solenoid,Vvt Solenoid Nissan Altima,Vvt Solenoid Valve

Wenzhou Zhongking Parts Co.,ltd , https://www.oemvvt.com